Hardware

Key words:

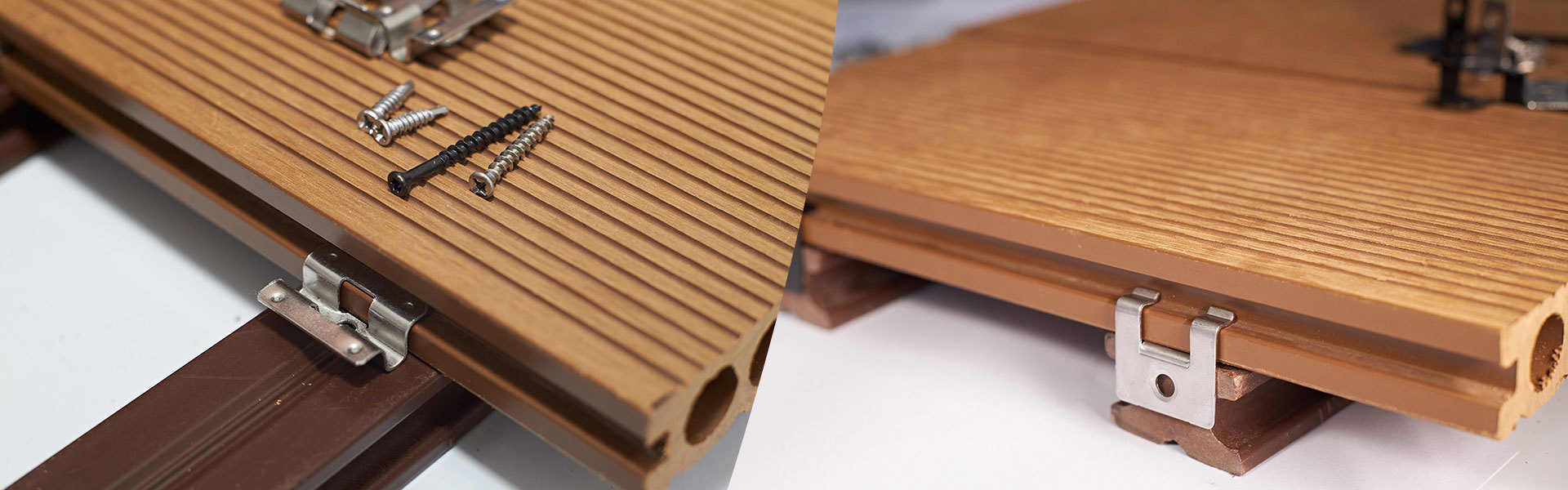

Butterfly buckle Wpc Decking Clips

Product advantages: larger and more solid shape, can be installed in two ways, easy to replace or repair the floor later. Can be removed in the middle.

Serrated buckle Quality Wpc Clips

Product advantages: unilateral sawtooth, installation is more stable, the floor will not slide left and right, so that the installation is more secure. It is convenient for later maintenance and replacement of the floor, with beautiful black surface and high corrosion resistance.

Starting buckle Customize Wpc Clips

Product advantages: start hidden installation, more beautiful, more convenient.

Product advantages: four claws symmetrical pressure on the floor, uniform force, stable.

Product advantages: thickened fasteners, greater pressure, more solid installation. Screw fixing in the middle is more convenient for later maintenance and floor replacement.

Product advantages: thorns on both sides add stability to your floor and prevent sliding. More solid.

Square thickened fastener 43*39

Product advantages: thickening and increasing, four claws symmetrically pressing the floor, the material thickness is 1.5mm, the bottom of the fastener is flat, it is easier to fit the keel, multiple screw holes are more fastened and not easy to loosen, and the life-long warranty is guaranteed.

Thickening is increased, the four claws are symmetrically pressed against the floor, the material thickness is up to 1.5mm, the bottom of the fastener is flat, it is easier to fit the keel, the fixing of multiple screw holes is more fastened and not easy to loosen, and the lifetime warranty is guaranteed.

Key words:

Newest Square Thickened Fastener

Product advantages: compact appearance, convenient installation, lower price.

Key words:

Quality Square Thickened Fastener

Product advantages: compact appearance, convenient installation, lower price.

Key words:

Product advantages: hidden installation of fastening parts, efficient installation is simple, the product price is lower than similar products, can achieve a variety of customer gap requirements, lower installation costs.

Key words:

Product advantages: the beginning and end of the dual-use hidden installation, is your floor according to the effect of more beautiful.

Key words:

Metal surface polishing treatment

Polishing is generally used for the finishing of the coating after plating, and can also be used for the pre-processing of the pre-plated parts. It is carried out on a polishing machine equipped with a polishing wheel. The purpose of polishing is to improve the smoothness of the product, so that the product can obtain a decorative appearance, improve the corrosion resistance of the product, and further remove the fine unevenness of the surface of the product.

Key words:

How to improve the automation level of metal stamping processing industry

Five areas of increased automation in the stamping and die manufacturing process, not only can help alleviate the shortage of existing skilled workers, but also can facilitate the future development of stamping manufacturers, these areas involve waste, fluid management and monitoring.

Key words:

The difference between hinge and hinge

Although hinges and hinges are mechanical parts used to open and close doors and windows or furniture, they have some differences in appearance, function, installation location and use method:

Key words:

Pretreatment process of aluminum surface treatment

Aluminum is extremely unstable in the air, and it is easy to generate an oxide film that is difficult to identify with the naked eye. Due to the different casting processes of aluminum parts, it is either directly sheared from rolled plates, or mechanically finely processed and formed, or formed by different processes and then heat treated or welded, etc. After the above different processing processes, the surface of the workpiece will leave different states and different degrees of dirt or traces. In the pretreatment process, the pretreatment process must be selected according to the actual situation of the surface of the workpiece.

Key words:

What types of hardware die casting manufacturers explain?

Hardware die-casting manufacturers can provide a lot of die-casting and supporting processing services for hardware machines and production accessories, according to different types of hardware accessories, die-casting methods will be used in the actual production process is also different, can achieve different results, then you know what types of hardware die-casting manufacturers have!

Key words:

What are the material characteristics of zinc alloy die castings?

In the field of modern industry, die casting structure as an important material component, has been widely used in various mechanical equipment and electronic products. Zinc alloy die castings, as one of the common types, have many unique material characteristics. This article will introduce the material characteristics of zinc alloy die casting in detail to help readers better understand this field.

Key words:

How to choose die-casting parts for electronic products?

When choosing suitable die-casting parts for electronic products, we need to consider many factors, such as the choice of materials, the rationality of the design and the advantages and disadvantages of the production process. This article will show you in detail how to choose die-cast parts for electronics and provide some suggestions so that you can make an informed decision.

Key words:

Hardware Die Casting Manufacturers: Types of Die Casting Alloys

Hardware die casting manufacturers, metal die casting is a kind of precision casting parts that use high pressure to force the metal melt into the complex shape of the metal mold. It is widely used in hardware and the entire machinery and electronics industry, including automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, construction, equipment, machine tools, ships, aerospace and many other fields.

Key words:

Hardware mold design and manufacturing complete process methods and methods.

Stamping mold production, generally there are several key links need our special attention and attention. Whether a set of moulds can be successfully handed in samples and produced the following points should be paid attention to by relevant mould personnel.

Key words:

Analysis of the advantages of aluminum alloy die casting

Aluminum alloy die-casting is a processing method in which aluminum alloy is melted and injected into a mold, and solidified under high pressure to form a desired shape. Has the following advantages:

Key words:

How to choose a suitable for you?

Let us assist you!

Our experts will contact you as soon as possible to meet your needs.

Product

Hot News